| . |

| Magnetec Inspection, Inc. |

Remote Field

| CORROSION |

| CORROSION |

| SLEEVING |

| SLEEVING |

| TANK FLOOR |

| ACFM |

| PIPING |

| CHILLERS |

| TANK FLOOR |

| ACFM |

| CHILLERS |

| PIPING |

| ECT |

| ECT |

| REMOTE FIELD |

| REMOTE FIELD |

| Magnetec Inspection, Inc. |

Remote Field Testing (RFT) is an electromagnetic test that makes use of an AC excitation source without any attempt at tube magnetization or saturation. The varying magnetic field is

affected by the abnormalities of the material. These changes in the field are measured a few tube diameters away from the source.

affected by the abnormalities of the material. These changes in the field are measured a few tube diameters away from the source.

The RFT system actually measures the primary magnetic field strength that exists at a given distance from the exciter coil. That field strength determines the included voltage across the

pickup coil. That voltage, expressed as a phase and amplitude vector with respect to the exciter coil, is represented on an X-Y screen in the standard format that most Eddy Current

Technology technicians can recognize. Through-transmission is sometimes used to describe the RFT process. It implies that there is a source of energy that transmits "through" a

medium.

pickup coil. That voltage, expressed as a phase and amplitude vector with respect to the exciter coil, is represented on an X-Y screen in the standard format that most Eddy Current

Technology technicians can recognize. Through-transmission is sometimes used to describe the RFT process. It implies that there is a source of energy that transmits "through" a

medium.

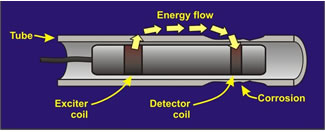

An RFEC probe consists basically of an exciter coil and a detector coil in a certain arrangement between each other. The probe is passed through the tube which shall be inspected.

The exciter coil is fed with a low frequency alternating current (normally sinusoidal) which causes an electromagnetic field around the exciter coil. The energy of the field spreads out in

axial direction inside the tube as well as into the tube wall. The eddy currents which are induced in the tube wall generate a secondary field which can be measured outside the tube.

This secondary field is much weaker than the primary field directly at the exciter coil inside the tube and has a significant phase shift. When testing thick-walled ferromagnetic metal

pipes with conventional internal probes, very low frequencies (e.g. 30 Hz for a steel pipe 10 mm thick) are necessary to achieve the through-penetration of the eddy currents. This

situation produces a very low sensitivity of flaw detection. The degree of penetration can in principle be increased by the application of a saturation magnetic field. However, because

of the large volume of metal present, a large saturation unit carrying a heavy direct current may be required to produce an adequate saturating field. The difficulties encountered in the

internal testing of ferromagnetic tubes can be greatly alleviated with the use of the remote field eddy current method, which allows measurable through penetration of the walls at three

times the maximum frequency possible with the conventional direct field method. This technique was introduced by Schmidt in 1958. Although it has been used by the petroleum

variations in wall thickness, but relative insensitive to fill-factor changes. The method has the added advantage of allowing equal sensitivities of detection at both inner and outer

surfaces of a ferromagnetic tube. With technique manipulation it can differentiate between signals from these respective surfaces. In its basic form, the probe arrangement consists of

an exciting coil and a receiver coil kept at a rigidly fixed separation along the axial direction.

The exciter coil is fed with a low frequency alternating current (normally sinusoidal) which causes an electromagnetic field around the exciter coil. The energy of the field spreads out in

axial direction inside the tube as well as into the tube wall. The eddy currents which are induced in the tube wall generate a secondary field which can be measured outside the tube.

This secondary field is much weaker than the primary field directly at the exciter coil inside the tube and has a significant phase shift. When testing thick-walled ferromagnetic metal

pipes with conventional internal probes, very low frequencies (e.g. 30 Hz for a steel pipe 10 mm thick) are necessary to achieve the through-penetration of the eddy currents. This

situation produces a very low sensitivity of flaw detection. The degree of penetration can in principle be increased by the application of a saturation magnetic field. However, because

of the large volume of metal present, a large saturation unit carrying a heavy direct current may be required to produce an adequate saturating field. The difficulties encountered in the

internal testing of ferromagnetic tubes can be greatly alleviated with the use of the remote field eddy current method, which allows measurable through penetration of the walls at three

times the maximum frequency possible with the conventional direct field method. This technique was introduced by Schmidt in 1958. Although it has been used by the petroleum

variations in wall thickness, but relative insensitive to fill-factor changes. The method has the added advantage of allowing equal sensitivities of detection at both inner and outer

surfaces of a ferromagnetic tube. With technique manipulation it can differentiate between signals from these respective surfaces. In its basic form, the probe arrangement consists of

an exciting coil and a receiver coil kept at a rigidly fixed separation along the axial direction.

The separation between exciting coil and receiver coil should be at least twice the inner diameter of the tube, preferably two and a half times, for the reasons explained below.

The exciting coil induces magnetic field in the normal manner; some of the field penetrates the wall of the tube and the rest remains within the tube's air space. Eddy currents follow

circular paths concentric with the axis of the tube flow within the tube wall and set up a reverse magnetic field. The reverse field weakens that part of the field remaining within the air

space, which decreases to zero before reaching receiver coil. The region that is active where the field induces directly by the exciting coil is called the direct field zone. This field can

produce a current in any coil suitably placed within the zone. The remote field zone is the region in which no direct coupling, or joining together, can take place between the exciting coil

and any receiver coil inside it. Small variations in the incident magnetic field can produce large changes in the resultant field, thus increasing the sensitivity of defect detection. With a

careful choice of frequency it is possible to resolve signals indicating variations of magnetic permeability from signals indicating the presence and size of defects.

circular paths concentric with the axis of the tube flow within the tube wall and set up a reverse magnetic field. The reverse field weakens that part of the field remaining within the air

space, which decreases to zero before reaching receiver coil. The region that is active where the field induces directly by the exciting coil is called the direct field zone. This field can

produce a current in any coil suitably placed within the zone. The remote field zone is the region in which no direct coupling, or joining together, can take place between the exciting coil

and any receiver coil inside it. Small variations in the incident magnetic field can produce large changes in the resultant field, thus increasing the sensitivity of defect detection. With a

careful choice of frequency it is possible to resolve signals indicating variations of magnetic permeability from signals indicating the presence and size of defects.